|

|

|

Home export products export products Chemical machinery Chemical machinery Non-metallic mineral equipment Non-metallic mineral equipment |

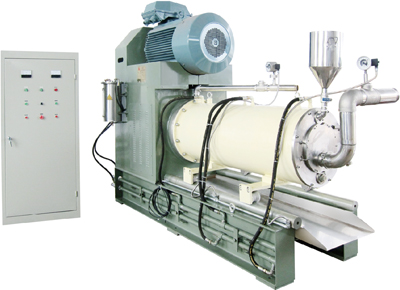

| CDS Large Flow Grinding Mill special for superfine powder |

|

The new full-volume Dynamic-Centrifugal-Cartridge-System offers optimized energy saving wet milling |

The new full-volume Dynamic-Centrifugal-Cartridge-System offers optimized energy saving wet milling technology by con-sequent combination of a multitude of newly developed and ideally matching functional elements. High efficiency grinding discs with a large-surface slotted sieve to get the better beads stributed in the mill chamber. Enhanced flow rate capability by centrifugal implement screen.

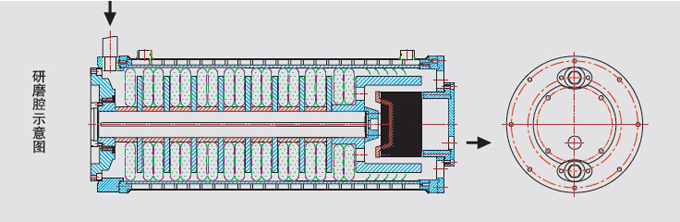

Operationally safe separation of grinding beads even with particularly high flow rates due to the highly efficient separator system, consisting of:

¡ñDeflector cage with integrate grinding disc

¡ñOuter deflecting shape of cage

¡ñLarge-surface slotted sieve

Concept and main features

¡ñElimination of all radial openings in the mill chamber

¡ñAllowing for installation of exchangeable, through-hardened inner liner

¡ñExchangeable, through-hardened front & end plates and hardened wear bushings at exposed locations

¡ñCombination of neutral and conveying high intensity agitator discs, specific design featuring increased diameter

¡ñBead retention by centrifugal implement screen

We can choose the grinding beads of diameter 0.2mm~1.0mm to grind materials, and it easily make materials¡¯ finess achieved submicron even nanometer.

On a conservative estimate and a equal conditions,the grinding efficiency is at least 2 times more than the traditional sand mill¡¯s.

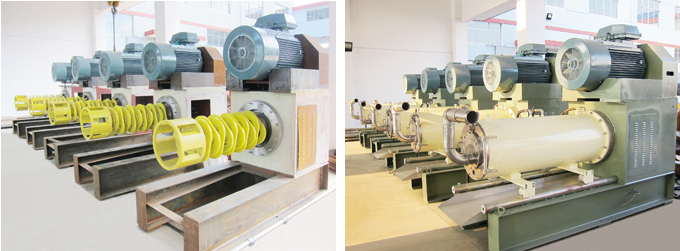

CDS Large flow rate grinding mill advantage

¡ñClosing gap between high enery density mills and convention mills

¡ñUsually singal pass process

¡ñUnique media retention device

¡ñUnique cleaning feature of large surface screen

¡ñAdvantageous grinding of abrasive products such as marine pains, antifouling ,heavy duty protective coatings

¡ñDispersing grinding of bulk paint (primer, filler)

¡ñEnhanced flow rate capability by centrifugal implement screen

¡ñEasy to exchange product contact parts

Wider application scope

|

Paints and coatings

¡ñPrimer and filler

¡ñElectrodeposit paint for the automotive industry

¡ñMarine paint, for instance antifouling formulations

¡ñCoil coating productsv

¡ñPaints and coatings even with higher viscosity |

| |

|

|

Printing inks for various applications

¡ñPublication gravure ink

¡ñExtender formulations

¡ñOffset concentrates

¡ñD i r e c t c o n v e r s i o n o f pigments into printing ink formulations |

| |

|

|

Chemical industry and specialties

¡ñTiO2 in organic solvent for textile fibre applications

¡ñMasses for catalysts

¡ñG r i n d i n g p r o c e s s e s during pigment production

¡ñPost-treatment of TiO2( s u l f a t e a n d c h l o r i d e process) |

| |

|

|

Minerals industry

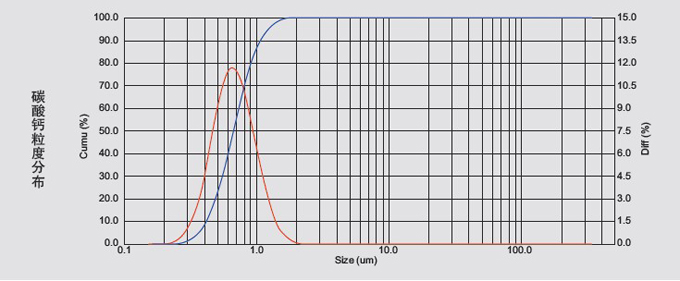

¡ñCalcium carbonate as filler quality and as paper coating masses

¡ñKaolin and talc for a variety of final applications

¡ñWet grinding in minerals processing |

| |

|

|

Ceramics industry

¡ñSuapensions of powders for engineering ceramics

¡ñCeramic materials

¡ñGlass-ceramic suspensions |

|

|

|

|